Visual AI in Industry Production & Quality Control

Smart inspection, faster production, fewer errors. AI-powered automation for modern manufacturing.

The Challenges Faced in Industry Production

Industrial production faces growing pressure to increase throughput, reduce defects, and optimize resources — all without compromising quality. Manual inspection and outdated automation often fall short in today’s high-speed environments.

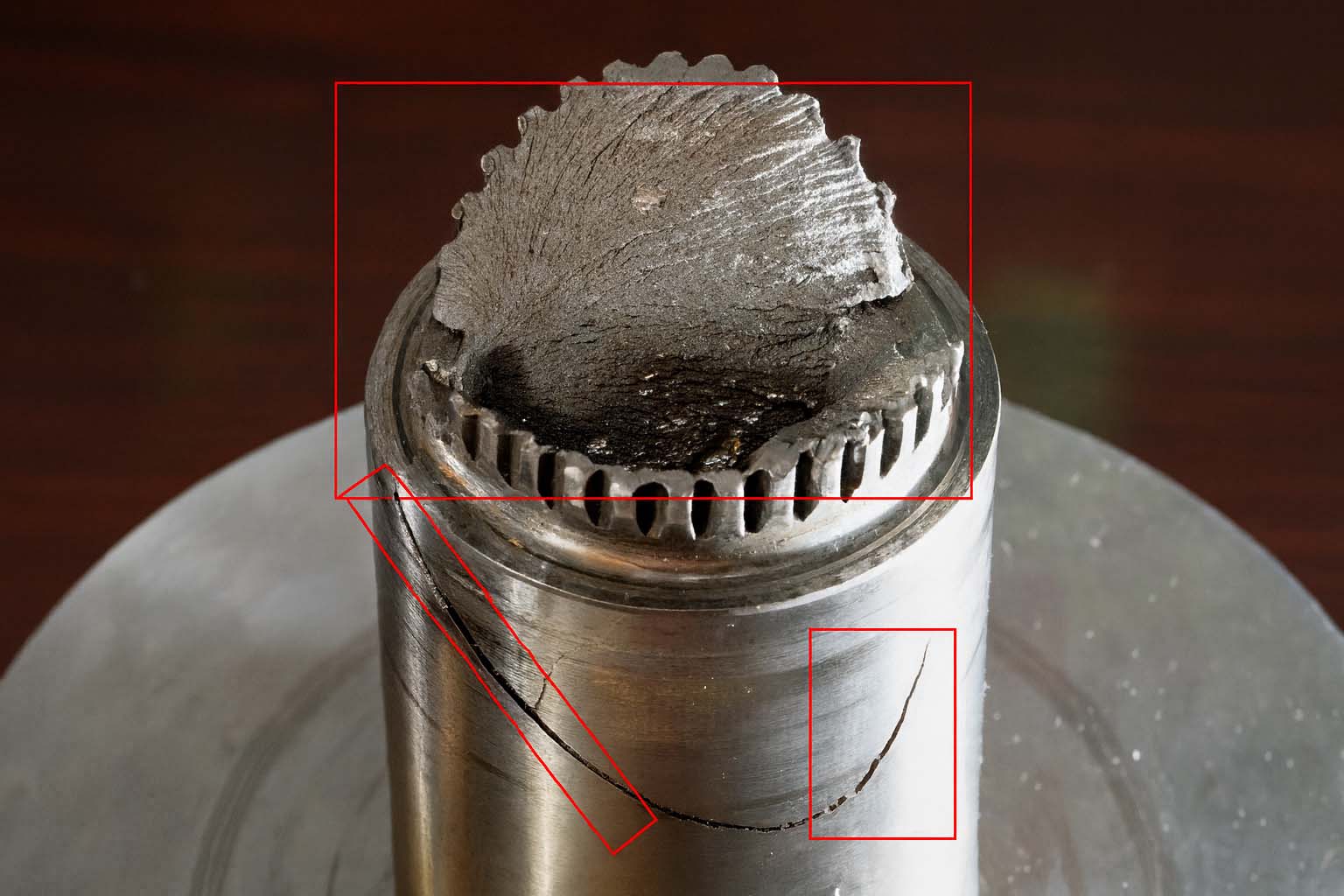

Missed Defects and Inconsistent Quality Checks

Visual inspection by humans can overlook small defects in high-speed lines or under poor lighting, leading to costly product recalls and customer dissatisfaction.

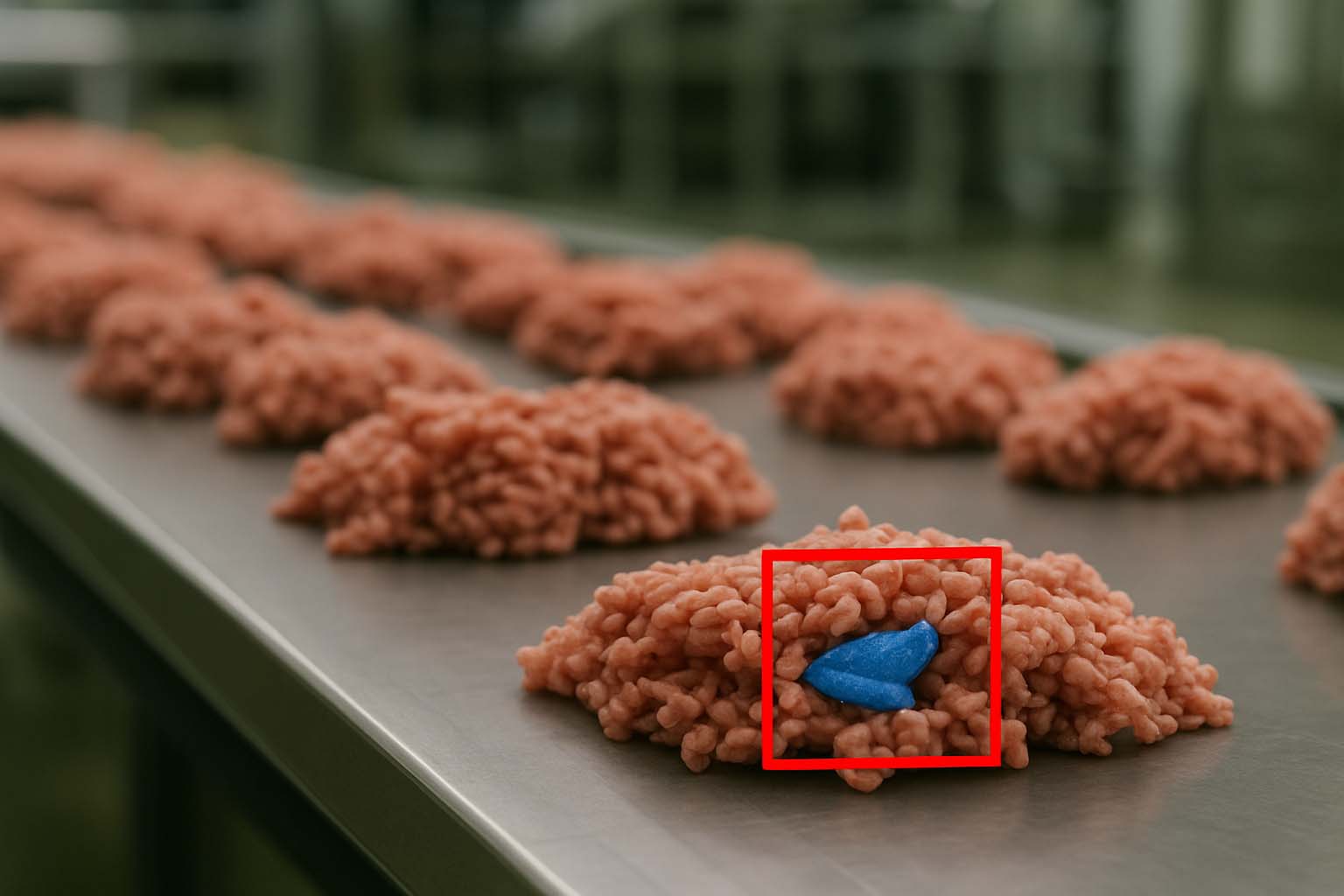

Undetected Foreign Objects or Material Issues

Contaminants or irregular materials may pass through unnoticed, damaging machinery or resulting in failed end-products — especially in food, pharmaceutical, and electronics industries.

Production Line Interruptions and Inefficiencies

Line stoppages, bottlenecks, or misalignments often go undetected until they impact output. Without real-time insight, operators can’t respond quickly or adjust processes in time.

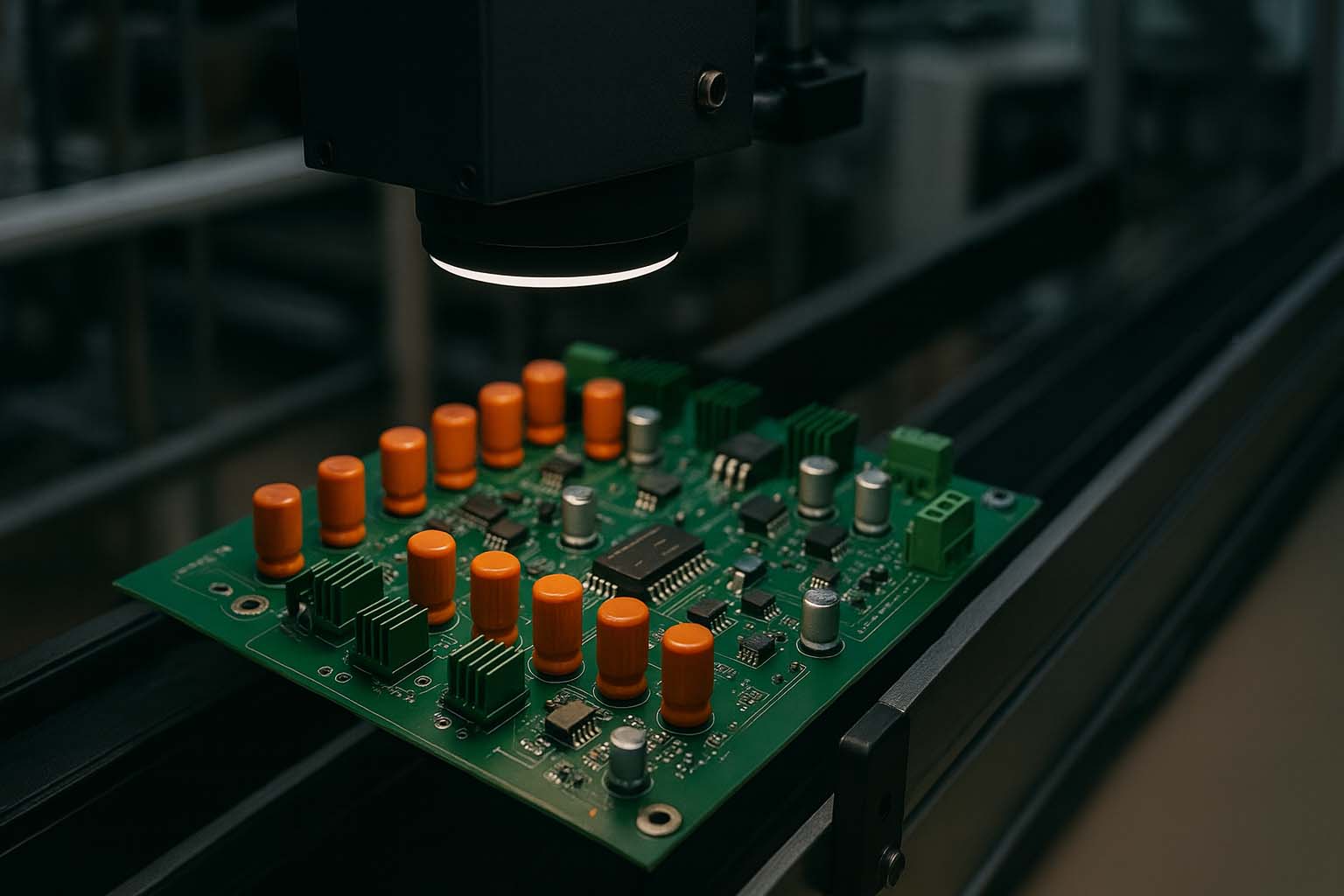

Streamlining industry production and quality control with AI Object Detection

Automated Quality Control

Visual AI detects surface defects, packaging issues, label misprints, or product irregularities in real time — ensuring every unit meets strict quality standards without slowing the line.

Automated Fence Line Monitoring

AI identifies foreign objects, inconsistent materials, and contamination instantly — protecting the integrity of components, preventing equipment damage, and enhancing safety in sensitive industries.

Intelligent Crowd Monitoring

Cameras track misalignments, detect unexpected slowdowns or stoppages, and analyze flow efficiency — delivering insights that help fine-tune production lines and avoid costly downtime.

Benefits of using airis:net in industry production

Higher Product Quality

Catch defects early, avoid customer complaints, and reduce rework. AI ensures every product meets your quality standards before it leaves the line.

Continuous, Scalable Monitoring

Unlike manual checks, airis:net works 24/7 without fatigue. Add more cameras and AI models as your production scales, without adding headcount.

Real-Time Alerts and Insights

Detect and act on issues instantly — not hours or days later. airis:net gives your teams the power to react before problems escalate.

Reduced Downtime and Waste

By identifying bottlenecks, stoppages, and defective processes early, airis:net helps reduce production loss, avoid scrap, and maintain maximum uptime.

AI-Powered Quality Control

Detect defects instantly on fast lines

airis:net inspects every product in real time, detecting defects, wrong labels, and sealing errors automatically. This ensures consistent quality at scale, lowers costly returns, and speeds up delivery of flawless products.

Get AI-Powered Quality Control

Ready to Automate Inspection and Optimize Your Factory?

airis:net helps you detect problems before they cause downtime, defects, or delays. Whether you’re manufacturing electronics, food, automotive parts, or consumer goods — our Visual AI platform adapts to your line.

Why Choose Us

AI-driven quality control solutions

airis:net transforms quality control with AI-powered automation, ensuring higher accuracy, consistency, and efficiency in production. From automated inspections to defect detection, our solutions adapt to your environment and scale across sites, reducing costs, minimizing errors, and improving production output.