Visual AI for Inspections

Automated insights for infrastructure, real estate, roads, and waste monitoring

The Challenges Faced by manual inspections

Whether it’s monitoring infrastructure, tracking property condition, or enforcing public cleanliness, traditional methods rely heavily on human labor, require dangerous field work, and suffer from subjective judgments. With growing infrastructure, aging assets, and higher public expectations, organizations need smarter, faster, and safer ways to inspect and maintain physical environments.

Time Consuming

Manual inspections are time-consuming due to the need for physical access, travel between sites, and detailed visual checks by trained personnel. Inspectors must document findings manually, often using photos and notes, which delays reporting and analysis. Repetitive tasks and human limitations further slow down the process and reduce efficiency.

Error-Prone

Manual inspections are error-prone due to human fatigue, inconsistent judgment, and varying skill levels among inspectors. Environmental factors like poor lighting or weather can affect accuracy. Missed defects, incomplete documentation, and subjective assessments often lead to unreliable results, increasing the risk of undetected issues and costly follow-up work.

Costly

Manual inspections are costly because they require skilled labor, travel expenses, equipment, and downtime during the inspection process. Accessing hard-to-reach areas often involves scaffolding or specialized tools. Repeated site visits, slow reporting, and human errors can lead to increased maintenance costs, delayed repairs, and higher operational expenditures over time.

Streamlining Realtime Inspections with AI Object Detection

airis:net brings the power of realtime Visual AI to inspection workflows. By combining advanced image recognition, anomaly detection, and real-time data processing, our platform transforms drone, mobile, or fixed-camera footage into actionable insights — automatically. From bridges to rooftops, from asphalt to waste bins, airis:net helps you detect issues early, prioritize repairs, and document violations — all without manual review.

Efficient Inspections

airis:net inspections are efficient because they automate defect detection, processes large volumes of images quickly, and ensure consistent accuracy. AI reduces the time needed for on-site visits, accelerates reporting, and identifies issues early. This streamlines workflows and enables faster, data-driven maintenance and decision-making.

Accurate and Reproducible Inspections

Visual computing AI with airis:net prevents errors in the inspection process by providing consistent, objective and reproducible analysis of images or videos. It detects defects with high accuracy, reduces reliance on human judgment, and flags anomalies automatically. AI ensures no detail is overlooked, minimizing missed issues and improving overall reliability and inspection quality.

Cost Savings

airis:net inspections can help to recuce consts because they eliminate the need for extensive manual labor, travel, and safety equipment. Automated analysis lowers operational costs, while early detection of issues prevents expensive repairs and extends asset lifespans.

Benefits of using airis:net for inspections

Increased Accuracy

airis:net detects defects and anomalies with high precision, reducing human error and ensuring consistent inspection quality across all assets, even in complex or hard-to-reach environments.

Faster Results

AI processes large volumes of visual data instantly, providing immediate insights and reports, which significantly speeds up decision-making and reduces delays in maintenance or repair actions.

Predictive Maintenance

By continuously monitoring asset conditions, visual AI identifies early signs of wear or failure, enabling proactive maintenance before serious issues arise — minimizing downtime and extending asset lifespan.

Enhanced Safety

AI-powered inspections reduce the need for human presence in dangerous locations, such as rooftops, bridges, or high towers, minimizing risk and improving workplace safety.

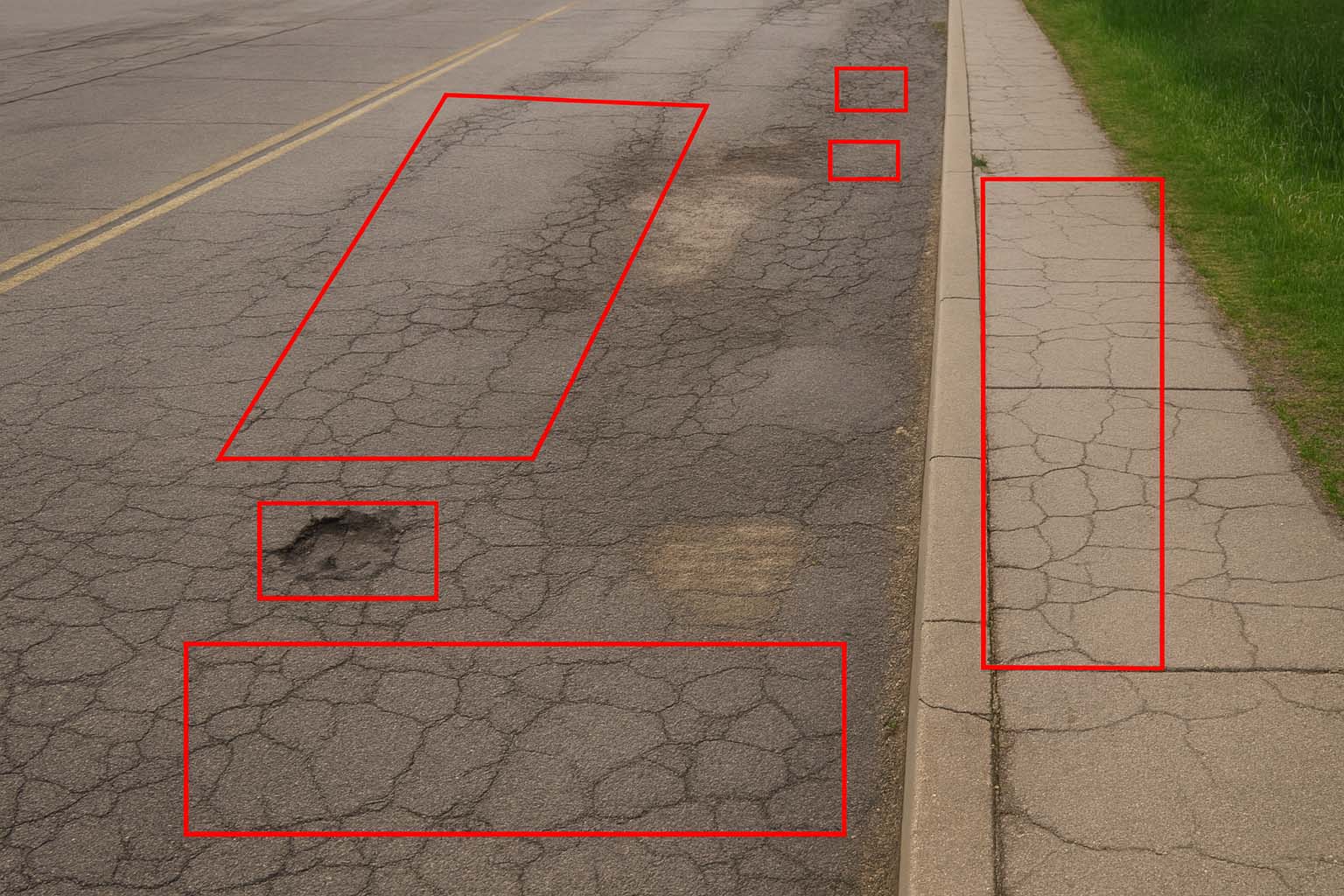

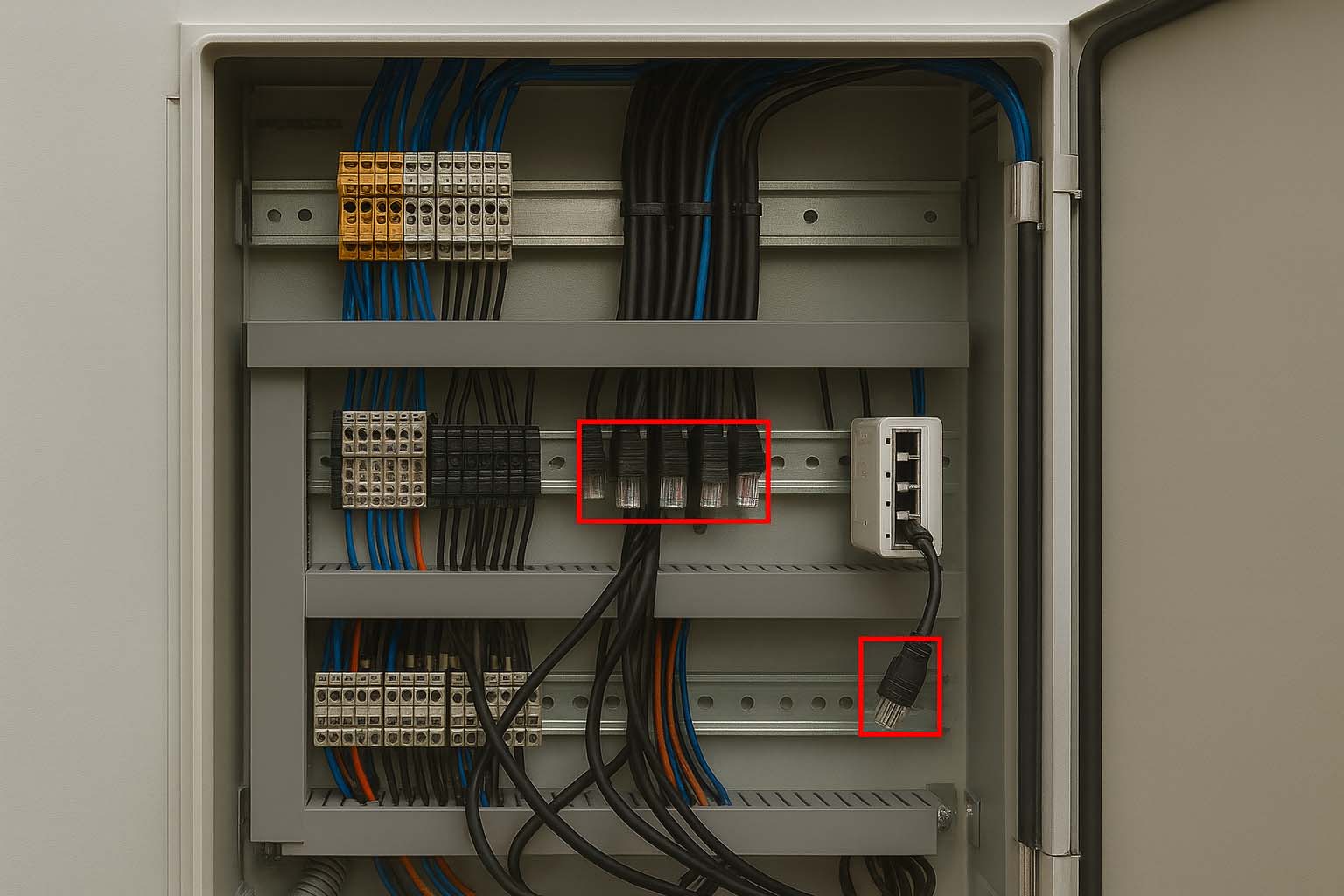

AI-Powered Visual Inspections

Smarter, faster, and safer infrastructure checks

airis:net Visual AI transforms inspection processes with drones and cameras, detecting cracks, corrosion, misalignment, and damage in real time. Reduce inspection time, improve safety, and generate accurate reports for reliable infrastructure maintenance.

AI-powered object detection for safe inspections

Why Choose airis:net for Smarter Inspections?

Inspection operations often face delays, errors, and risks due to manual review. airis:net automates inspections with AI-powered object detection that flags and classifies issues instantly with image evidence. This ensures safety, compliance, and efficiency while reducing costs, preventing damage, and enabling smarter, data-driven decisions across sites.